Moore-Built, Inc.

877-976-7675

www.moore-built.com

Established in 1994, Moore-Built manufactures standard and super duty types of toolbars, row markers, lift assist wheels, gauge wheels, etc. for agricultural purposes such as planting, fertilizing, cultivating and strip-till.

Established in 1994, Moore-Built manufactures standard and super duty types of toolbars, row markers, lift assist wheels, gauge wheels, etc. for agricultural purposes such as planting, fertilizing, cultivating and strip-till.

The trussed main bar is built heavy-duty for strength and rigidity. Parallel stacking arms spaced wide for increased transport stability and lifting leverage. Hydraulic wing flex lets wings up or down as well as flexing up for turning at the end of the field. Moore-Built has a 35-degree vertical folding toolbar that can be custom made for virtually any application.

Welded 3-point hitch can be used for dual applications in side-dressing. An extra set of hitch plates is added for 15-inches off the row center.

Monosem

913-438-1700

www.monosem-inc.com

Monosem produces a wide range of highly engineered built-to-order custom planters.

Monosem produces a wide range of highly engineered built-to-order custom planters.

Many row crop producers have found the precision meter an important advantage to save on seed costs while delivering those seeds to their best potential.

This unique cast aluminum meter with its stainless steel seed plates, brass seed scraper and brass ejector block provides the qualities of dependability, durability and versatility that have become synonymous with Monosem.

The Monosem meter uses a brass ejector to direct seeds off the flat seed plate at the same angle of release. This ensures that every seed is dropped at the same location of the seed tube to produce consistent seed spacing.

The singulator, flat seed plate and ejector are unique features to this meter and working together enable it to both singulate and deliver spacing with precision, which are critical to uniform size and higher tonnage with sugarbeets. For producers growing alternative crops like corn, sunflower or soybeans, a quick change of the seed disc and transmission adjusts for population rate and seed size.

Monosem offers multiple configurations specifically for the sugarbeet farmer including three linkage types, many forward attachments and specific options like brackets to accommodate new insecticide systems and 3/4 bu. receiving hoppers on the Central Seed System for planting both corn and beets.

For linkage choices, the newest is a Monosem exclusive, the Monoshox.

The Monoshox adjusts to a full range of down pressure while the integrated shock absorber provides dampening to reduce upswing bounce from the row unit. This dampening provides better ground contact for accurate depth control at higher speeds which translates to even emergence.

Studies have shown uneven emergence as a significant factor in yield loss.

Sugarbeet configurations include 3-pt mounted up to 12-row, Mounted Stackers up to 24-row, Centerflex Pull-Type up to 24-row, and the Narrow Transport Pull-Type up to 36-row.

The Narrow Transport toolbar with high clearance and shorter transport length gives producers efficiency options like 100 BU Central Seed System, 1,000 gallons of liquid, and for concerns about compaction, optional tracks and flotation tires.

Schaffert Mfg. & Sales

800-382-2607

www.schaffert.com

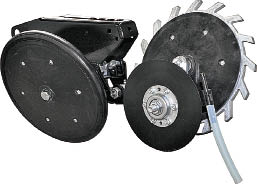

Schaffert Mfg. & Sales has introduced the new Generation 2 - 2 x 2 Fertilizer Disc. Its unique one-piece design will keep the down pressure even on both press wheels as they move in unison. The arm of the G2 is mounted on a pivot point that is grease able and attaches to the tail section with 4 bolts.

Schaffert Mfg. & Sales has introduced the new Generation 2 - 2 x 2 Fertilizer Disc. Its unique one-piece design will keep the down pressure even on both press wheels as they move in unison. The arm of the G2 is mounted on a pivot point that is grease able and attaches to the tail section with 4 bolts.

The G2 has similar features of our original 2 x 2 system, but with improved depth management. The disc mounting arm provides ½- to 2-inch depth placement. There are three adjustment holes, which allows movement up or down of the disc.

Also, tires can be spaced in and out with shims, depending on depth of planting. The 2.5 mm, 8-inch disc allows for improved depth, and with a larger beveled edge, which dramatically improves cutting even in the toughest soils. The thick blade slices into the soil letting the fertilizer penetrate to the bottom.

Schaffert switched to a wider spindle bolt and added a grease zerk to allow for internal lubricating. These improvements allow continual movement and increased stability. The new G2 still utilizes the same triple sealed bearing, designed for harsh conditions.

The new G2 liquid disc will accommodate most spiked closing wheels. Operators can also remove the disc when fertilizer is not needed.

The new G2 liquid disc will accommodate most spiked closing wheels. Operators can also remove the disc when fertilizer is not needed.

It will work on most John Deere, Kinze (after market), White, and 2- hole adjustment tail sections.

The new G2 addresses a few of the limitations of the successful counterpart G1 version. With a central mounting of the walking beam arm, equal distribution of down pressure is maintained with the closing wheels never sacrificing the closing of the furrow.

This allows for a consistent creation of a "2.5 mm slit" with the 8-inch blade for the fertilizer to penetrate below the soil.

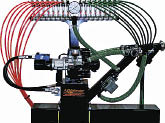

The new AgXcelerator line of customized Fertilizer Application Systems enables customers to select from a series of fully assembled, pre-packaged, turnkey systems that tie into their existing equipment manufacturer (OEM). They can build a system that will fit specific requirements and budget. The customized AgXcelerator Fertilizer Application Systems (AgX FAS) have everything needed to get up and running.

The company that has over 35 years of experience. For precision liquid placement, use the Rebounder Seed Covers with optional fittings for in-furrow application or our 2x2 Fertilizer Disc for high volume output; both are designed to work with our Fertilizer Application Systems.

"Customer's like the control they have of being able to adjust the volume accurately in the cab, and that it ties into their existing equipment. They also love the fact it comes pre-assembled, ready to bolt on and go. It saves them time and money." says Ramiro Trevino, VP of Product Development at Schaffert Mfg.

Ag-Vantage, Inc.

208-670-1041

Jeff Jarolimek

www.ag-vantage.com

We offer a complete kit to mount Rolling Shields to your planter. Our kits allow you to deep rip the centers of the rows without covering up your seed. This will help prevent wind erosion and allow better water penetration. We can sell you just the Rolling Shields or we can do the complete planter setup that would includ all the extension brackets, penatrator shanks, rolling shields and all the other hardware to allow you to bolt it to your planter. The shields are 24 inches in diameter and are mounted to a floating arm, which then mounts to a 2-inch tube.

We offer a complete kit to mount Rolling Shields to your planter. Our kits allow you to deep rip the centers of the rows without covering up your seed. This will help prevent wind erosion and allow better water penetration. We can sell you just the Rolling Shields or we can do the complete planter setup that would includ all the extension brackets, penatrator shanks, rolling shields and all the other hardware to allow you to bolt it to your planter. The shields are 24 inches in diameter and are mounted to a floating arm, which then mounts to a 2-inch tube.

We also offer the Culti-Diker that will allow you to form small water retaining pockets at planting. They bolt to any S-Tine or they can be mounted to a 2- or 2 ½-inch tube. They allow you to prevent runoff problems right at planting. They only weigh 55 pounds and have 35 pounds of down pressure. They form 4- to 8-inch pockets.

We also offer the Culti-Diker that will allow you to form small water retaining pockets at planting. They bolt to any S-Tine or they can be mounted to a 2- or 2 ½-inch tube. They allow you to prevent runoff problems right at planting. They only weigh 55 pounds and have 35 pounds of down pressure. They form 4- to 8-inch pockets.

Starco Manufacturing, Inc.

800-859-0399

Casper, WY

www.miltonplanters.com

The Milton Precision Planter is capable of consistently producing higher yielding crops. Precision seed placement allows for optimal plant growth, while eliminating thinning and reducing seed and fuel costs. The Milton Precision Planter will plant down to 11-inch rows on a single toolbar.

The Milton Precision Planter is capable of consistently producing higher yielding crops. Precision seed placement allows for optimal plant growth, while eliminating thinning and reducing seed and fuel costs. The Milton Precision Planter will plant down to 11-inch rows on a single toolbar.

The precision seed planter Milton, takes everything that growers love about the original Milton and repackages it in a smaller, narrower design. The narrower design allows for planting 8-inch rows on a single toobar or 4-inch rows on a double tool bar.

Like the original Milton Precision Seed Planter, the Milton uses interchangeable seed wheels and drive gears to give unparalleled planting options. This planter can seed virtually all small-seeded crops, including onion and sugarbeets, and is especially well-suited for growers seeking to increase their yield without increasing their acreage.

This planter features interchangeable seed wheels and drive gears, which give the planters a nearly infinite number of seed-spacing options. They provide a wide-range of seed wheels and eight pack wheel options. It automatically meter seeds at varying ground speeds, which virtually eliminates skipped and damaged seeds. Precision placement eliminates thinning and reduces seed and fuel costs. The "high-rise" toolbar linkage is adjustable for planter down-pressure when flat planting or planting on beds. The heavy-gauge steel discs open a clean furrow. Then the seeds are placed using a unique process of carrying each seed on a custom-machined seed wheel that rotates inside a formed downspout, delivering each seed individually into the furrow at a specific depth. The seed drop is very short (less than 3-inches), virtually eliminating ricochet, and the static-free process also eliminates static interference with seed placement.