This buyers' guide appears in the May 2021 issue of Sugar Producer.

H&S Mfg., Inc.

(800) ROW-CROP

H&S Beet Cart

On the company’s 50th anniversary, H&S Mfg. announces the new, added offering of a 44-ton beet cart model size. H&S now offers 24-, 30-, 35- and 44-ton beet carts. H&S carts add efficiency to keep the harvester moving during the short window of fall beet harvest. Operators can continue operating even in very muddy conditions with tracks or large flotation radial tires.

Available unloading boom sizes include 42-, 52- and 64-inch widths. The elevator boom provides for fast unloading while scrub-cleaning the beets for grower tare incentive payments. The unload speed can be optimized with the available tractor to drive the elevator by hydraulics or PTO. Convenient water kits and scale options are available, along with new plastic wear strips as an option for the bed chain conveyor.

With the experience of nearly 30 years manufacturing sugarbeet carts, H&S has developed a cart with the customer’s needs in mind.

Parma Company

(208) 722-5116

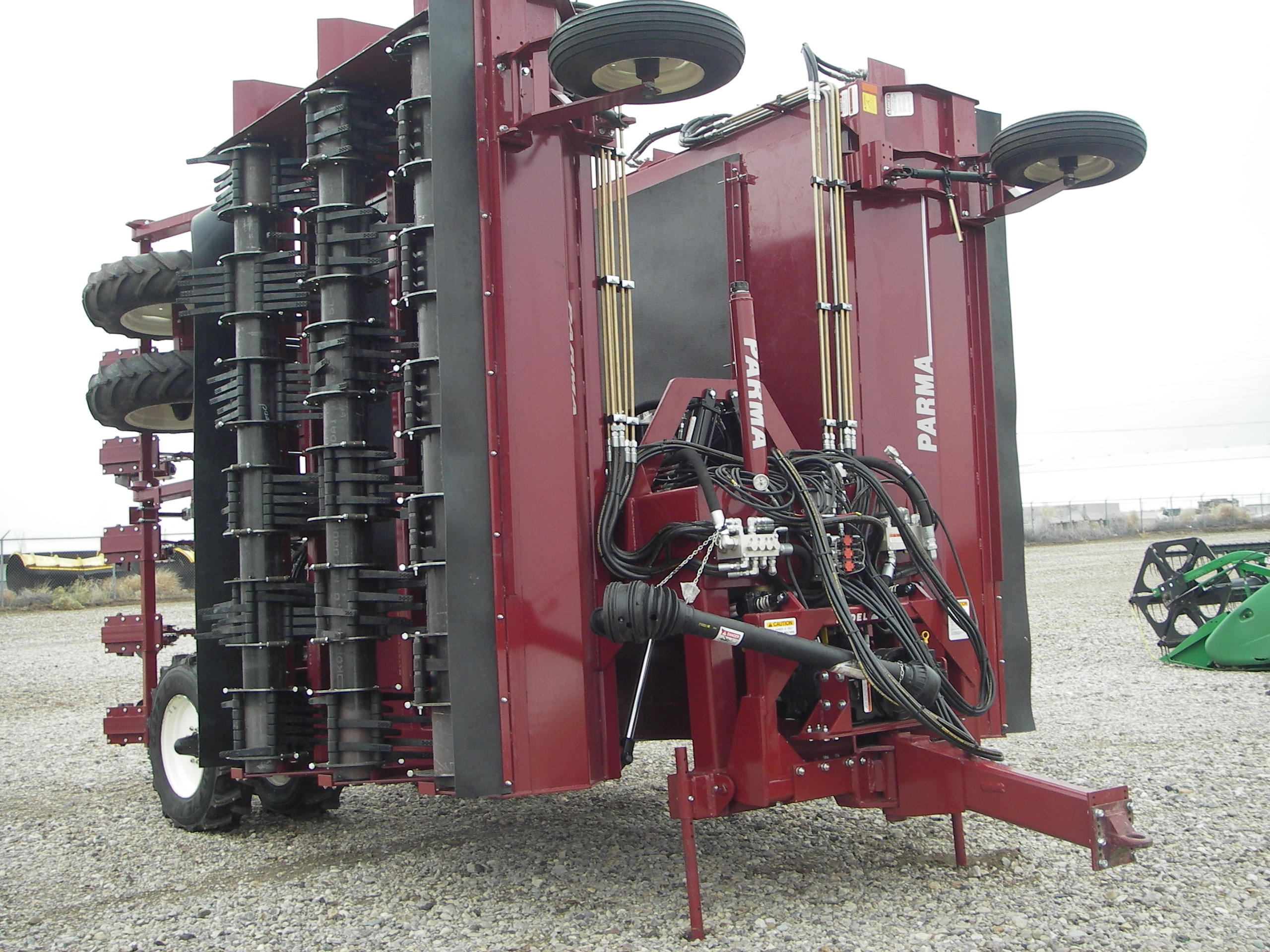

Parma Defoliators

Parma sugarbeet defoliators are simple and economical and provide the cleanest beets ready to harvest. Model sizes vary from four to 12 rows. The front drum is designed with a time-proven steel cup flail rotor driven with simple banded belt drives to keep repair costs to a minimum. The updraft action of the cup flail provides the best topping of any system on the market. Large, 24-inch wheels and tires provide easy, smooth rolling through wheel tracks and corrugates.

Three types of scalper options are available: the simple knife, the simple unpowered disc, and the hydraulic-driven disc.

Parma Harvesters

Parma sugarbeet harvester models are available for varying harvesting needs allmodels are built for high-yield capacity harvesting and cleaning, with simplicity and durability in mind. Harvester sizes range in row spacing configurations from four to 12 rows.

Rear elevator harvester models use high-quality belted chain for seasons of reliable lifting. The rear wheel models use a simple center axle-driven wheel to gently carry beets to the hopper. Both systems deliver a cleaner, whole beet to the truck

Parma’s 12-row, double-elevator harvester maintains these same standards while providing economical, high-capacity harvesting. These ever-improving designs come from the experience of over 60 years of building sugarbeet equipment.

Amity Technology

(701) 232-4199

Crop Chaser Multi-Crop Dump Carts

Amity’s Crop Chaser dump carts, including the CC1000 single-tank model and CC2000 double-tank model, feature a track undercarriage, which greatly reduces compaction and improves flotation when compared with trucks or wheeled dump carts.

The Crop Chaser series was engineered to add reliability and consistency to harvest operations. Trucks can be kept on field headlands, allowing crews to run more consistently with fewer weather delays, while helping to prevent the trucks from dragging large amounts of mud onto roadways. Furthermore, one cartload equals one truckload in most cases, providing a better flow of trucks running to the storage site, compared to using smaller dump carts.

The CC1000 single-tank model includes patented independent front and rear live wall chains for controlled unloading. It uses four hydraulic remotes for the tank lift cylinders and chains, giving operators maximum control over the dump rate. The CC2000 double-tank model has two separate tanks to split the load for natural control and stability when one tank is dumped at a time. Special load-holding valves provide added safety by preventing the load from moving in case of an unforeseen hydraulic issue.

An integrated scale is standard on Crop Chaser dump carts to further improve harvest logistics by eliminating the need for trucks to run over a scale before dumping. Three sensors (one on each track and one on the hitch) provide a highly accurate weight measurement of each load.

Other standard features include concentrated greasing locations for quick and easy routine maintenance and work lights for enhanced nighttime visibility. A camera system is optional to better monitor loading and unloading from the cab. The CC1000 and CC2000 can be ordered with a left- or right-hand dump. The modular design of these carts also allows the dump side to be flipped later if desired.

2720 Sugarbeet Harvester

.jpg)

The new 2720 sugarbeet harvester offers several improvements and new features to make harvest more efficient. The 12-row harvester utilizes a 31 percent higher volume scrub tower and Amity’s Dynamic Chain Management to allow harvesting capacity that allows for well beyond 45 tons of beets at 5 miles per hour. In addition to more scrub elevator capacity, Dynamic Chain Management helps extend the life of scrub chains.

The new harvester also offers new transport options of 900/60R32 tires or a 30×67-inch track system. Optional Active Depth Control has also been updated with a dramatically new interface for easier operation and is now ISOBUS-compatible to help reduce the number of screens in the tractor cab. Newly designed side doors on the 2720 also provide easier access to maintenance points and adjustments.

Safe-T-Pull Manufacturing Inc.

(701) 284-6100

Crop Shuttle

The Crop Shuttle is the largest, fastest and most versatile crop cart on the market. It is fully customizable, with a capacity of up to 46 tons and discharge speeds of up to 25 tons per minute. The Crop Shuttle is extremely versatile, allowing for use in multiple crops such as sugarbeets, potatoes, carrots, onions, red beets, cucumbers and even corn silage.

New for 2021 is an attachment for the Crop Shuttle so producers can use it to spread lime. The Lime Spreader attachment allows growers to get more from their investment and can be left on during regular harvest. This means it can be used to pre-harvest beets in the morning and spread lime ash in the afternoon with no time to switch over.

The Crop Shuttle is fully customizable to meet individual grower needs and features multiple cleaning bed options that allow operators to remove tare and leave the dirt in the field.

Strong Box Live Bottom

Strong Box live-bottom belted trailers and bulk beds allow operators to have versatility across many crops by allowing them to unload quickly and gently. Unlike an end-dump, drivers can control unload rate and have greater stability by keeping a low center of gravity, even on sloped ground. Wet materials such as lime and manure that are known to stick to end-dump walls and cause rollover accidents can easily be hauled.

Strong Box’s powerful, positive chain-drive belted floor ensures no slippage, providing a fast unload rate that is smooth and gentle. Enclosed side walls provide great aerodynamics and a clean look. The trailer also provides flex where you want it and strength where you need it.

Options include 30-, 36- and 50-inch belt widths, multiple axles, gas-powered hydraulic units, multiple rear door options for numerous crops, and various overall lengths and side wall heights.

Safe-T-Pull Pro

.JPG)

The Safe-T-Pull system consists of a truck hitch that fastens to a truck’s existing tow hook mounts, providing a centralized loop to pull from, and a hydraulically operated tow bar that mounts to the drawbar of a tractor, forage harvester, payloader or bulldozer.

This system saves time and money, and gives the added safety of eliminating dangerous ropes, chains and cables. The system is strategically designed to pull from both frame rails, reducing the risk of damage. The entire system is completely operable from the comfort of the cab — no need to get out to hook up. Drivers can even unhook on the go.

Ropa North America

(810) 705-0297

Tiger 6 XL

Ropa has now developed the Tiger 6 XL with a unique hydraulic suspension and slope compensation, more capacity and an R-concept information and control system. Higher efficiency per acre, more comfortable handling and lower fuel consumption are achieved with this 700-horsepower machine. This a self-propelled harvester defoliates, cleans and bunkers 30-plus tons, unloading on the go.

Big Bear

The Big Bear sugarbeet cart is a quick way to transport beets from the harvester to the truck or clamp.

Both 35- and 40-ton models ensure quick unloading by hydraulically driven conveyors to the center conveyor keeping a balanced load at all times. Track undercarriage keeps compaction at a minimum, and allows harvest of beets in very adverse conditions. Scrub roller provides cleaning action as beets pass from center floor to the truck conveyor. Select left- or right-hand unload with or without hydraulic lift.

Euro Maus 5

Ropa presents a new generation of its self-propelled cleaning loader for sugarbeets with entirely new dimensions and a collection system more than 33 feet wide.

The overall concept combines performance and efficiency and blends practical experience with the newest technological innovations from Ropa. The unmistakable feature of the Maus is its 30-foot-long counterweight arm, specially designed to guarantee utmost stability, even when its unloading conveyor is extended to 50 feet.

Art’s Way Manufacturing

(712) 864-3131

6812 Harvester

The Art’s Way 6812 sugarbeet harvester sports some of the most durable digging struts and paddles to get beets out of the ground and onto a bed of transfer rolls. Growers have the option of choosing new, heavier lifter wheels for more durability in the field. From there, four sets of cleaning rolls provide the highest cleaning capacity on the market. A low-maintenance wheel elevator moves the beets to the top of the machine and into the 4.5-ton holding tank. Available with steel or poly-coated rolls, fixed or flex struts, and several axle options, the 6812 can be customized for each grower’s individual digging conditions.

Adaptive Leveling Technology (ALT)

The new ALT system from Art’s Way allows for adaptive digging across any field. Featuring a hydraulically operated axle and sonar sensing, the operator is able to monitor and adjust digging depth across the field from inside the tractor cab. With more precise control over the machine, harvest can run more efficiently.

Spudnik Equipment Co.

(208) 785-0480

Scorpion Harvester

.png)

Spudnik’s Sporpion sugarbeet harvester is a durable, ruggedly built harvester that is easy to operate and gentle on sugarbeets. Among its distinguishing features are its scorpion-tail-shaped beet elevator, five-point paddle shaft, large-diameter puller wheels, and multi-axis control electronic row finders. Because of its five-point paddle shafts and large-diameter puller wheels, it is gentle on beets even when operating at higher ground speeds. It is available in six- (3060), eight- (3080) and 12-row (3120) configurations.

Holmer Americas

(989) 553-5253

Terra Dos T4-40

Intelligently networked and perfectly constructed, the self-propelled Terra Dos T4 sets new standards and is a milestone in sugarbeet harvesting.

The unique Holmer EasyLift system guarantees the best harvesting results. Its lightweight construction provides unrivaled soil protection, the chassis concept with integrated slope sensor ensures stability in all situations, and the intelligent Holmer EcoPower combines the best performance with the lowest fuel consumption.

Customers can also choose the two-axle version—the Terra Dos T4-30—if it better suits their individual need.

The Terra Dos T4-40 at a glance:

- Holmer EasyLift patented automatic single-row depth control

- HR 12-row lifting unit

- HR lifting unit with seven rollers for optimal cleaning

- Multiple topping options for individual adaptation

- Holmer DynaCut scalpers with longer and sharper knife edges

- Holmer DuraShare for minimal wear costs

- High-flotation Michelin tires

- Three driven axles to work even under the wettest conditions

- Intuitive operating concept Holmer SmartDrive for efficient and ergonomic operation

- 32-ton bin capacity

- Right- or left-hand discharge available on request

Terra Felis 3 evo

The Terra Felis 3 evo is the most modern beet cleaner loader in the world. It is setting standards in gentle and efficient beet-loading—demonstrated most obviously by the pick-up header that has been developed and patented by Holmer.

From the liftable cab to the fast automatic folding system, the Terra Felis 3 evo offers the utmost in comfort. The cleaning concept can be individually customized and offers solutions for all use conditions. A 32-foot pick-up header width, 49-foot transfer loading range, and intelligent counterweight synchronize the overall concept.

The Terra Felis 3 evo at a glance:

- 381-horsepower Mercedes Tier V engine

- New hydraulic drive concept

- Patented pick-up header for more flexibility in cleaning

- Four different post-cleaning variations for adaptation to individual local conditions

- Liftable cab

- Practical counterweight arm