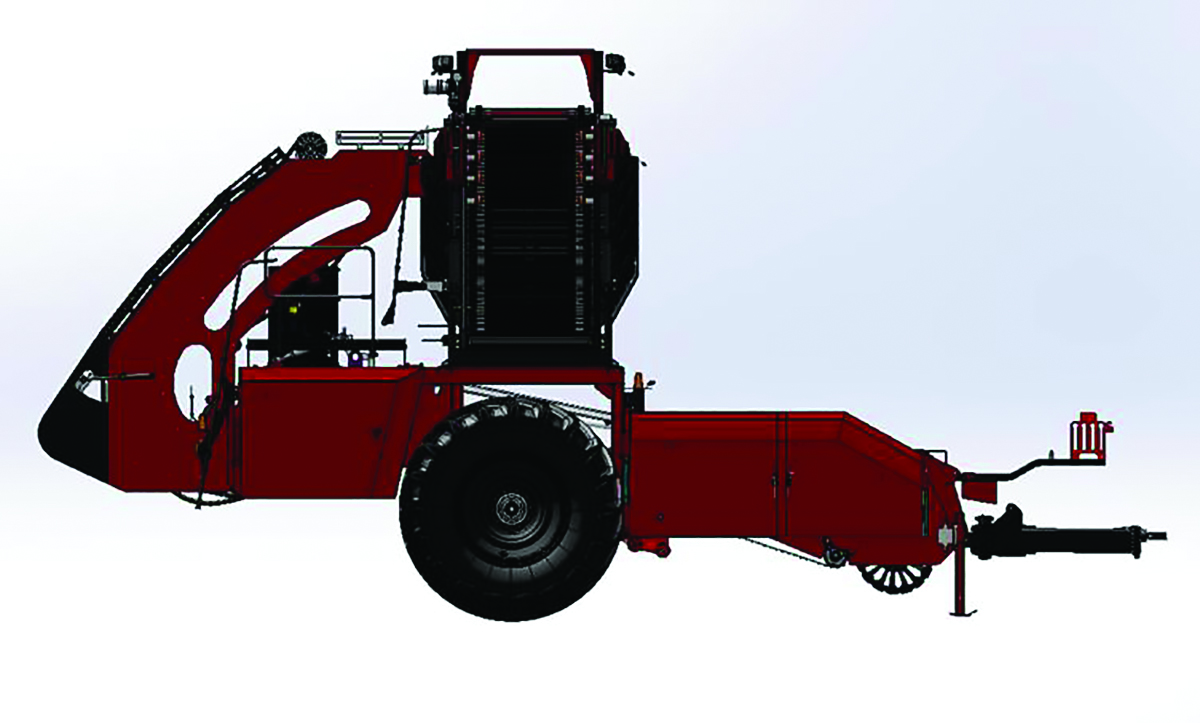

Amity Technology introduces its next advancement in sugarbeet harvesting. The new 2720 sugarbeet harvester offers several improvements and new features to make sugarbeet harvest more efficient. This 12-row harvester utilizes a higher-volume scrub tower, Dynamic Chain Management, ISOBUS active depth control, newly designed maintenance access doors, and an option for larger tires—or even tracks.

The redesigned scrub tower is the standout feature to the 2720—Amity’s newest and largest beet harvester. The new, widened path that harvested beets follow to the top of the machine can hold up to 31 percent more beets. This creates the potential for increased throughput during harvest.

Dynamic Chain Management is also now standard on the scrub elevator. This feature helps lengthen the life of the scrub chains by properly managing the tension on the pendulum that helps take up slack when the harvester is not at maximum capacity. Dynamic Chain Management allows the harvester to handle almost anything from the thinnest stands and lightest tonnage, to more than the heaviest tonnage per acre growers can raise today.

The 2019 harvest proved to be a major challenge for growers. In the Red River Valley growers were plagued by excessive moisture, making it difficult to keep the harvester on top of the ground while digging sugarbeets. Amity recognized this and quickly went to work developing a way to help growers do just that. This led to a couple new transportation options for the 2720 harvesters. The 2720 will now have the option for 900/60R32 tires or a 30- by 67-inch track system to help with not only flotation in wet conditions, but reducing compaction and increasing stability at all times.

“Higher-tonnage crops and a small harvest window have led us to develop a higher-efficiency machine,” says Brad Meyer, vice president of sales and marketing for Amity. “Field tests for the 2720 harvester have shown capacity capabilities well beyond 45-ton beets at five miles per hour. Additionally, the optional track system helps keep the harvester running when conditions are challenging.”

Installed software on the new harvester will allow optional Active Depth Control to work with any ISOBUS terminal, decreasing the number of screens in the cab of the tractor. The user interface of ADC has also been dramatically updated to allow for more intuitive operation. New side doors on the 2720 also give easier access to maintenance points and adjustments, making it quicker to get back to harvest.

Contact Amity Technology at www.amitytech.com.

.jpg)